A guide to sanding and finishing an epoxy table

There is something special about a piece of furniture that offers something more than functionality. Furniture making can be seen as a form of expression and has seen many designs...

Improving efficiency is all about working smarter, not harder. Improving work efficiency and reducing the risk of costly errors is possible, by choosing the right type of equipment for sanding and polishing all kinds of surfaces.

Mirka power tools have:

Wood sanding without dust

Exposure to dust poses many hazards to the health and safety of millions of workers. Dust in the workplace can also contaminate or reduce the finishing quality of products and affect worksite productivity. But it’s all preventable.

Try Mirka's pioneering sanding solutions and see how a dust-free working environment can boost your business.

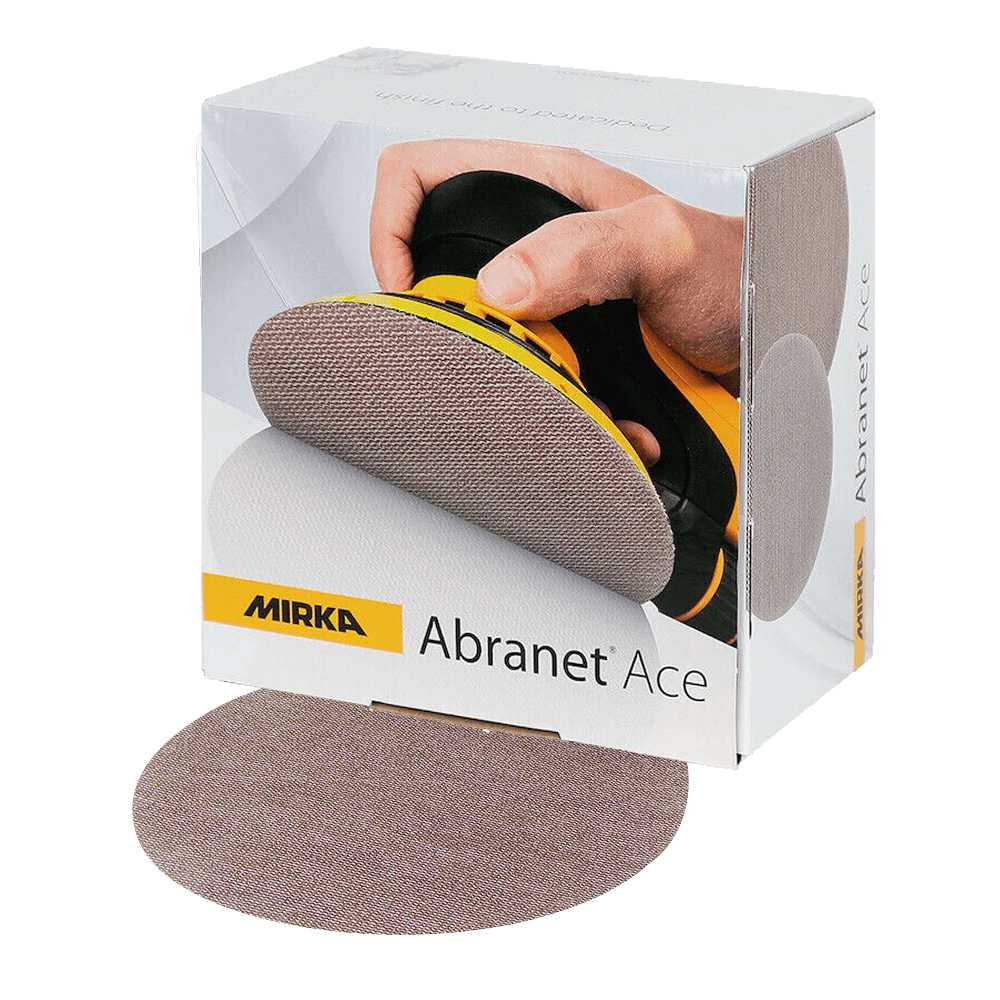

Thanks to the optimzed net construction and ceramic grains, Abranet Ace offers superior cut and performance for hardwoods (such as beech and oak) and fast cutting on various solid surface materials as well as for cleaning of different industrial rollers. Abranet Ace also works excellent on primer sanding applications.

Want to work faster?

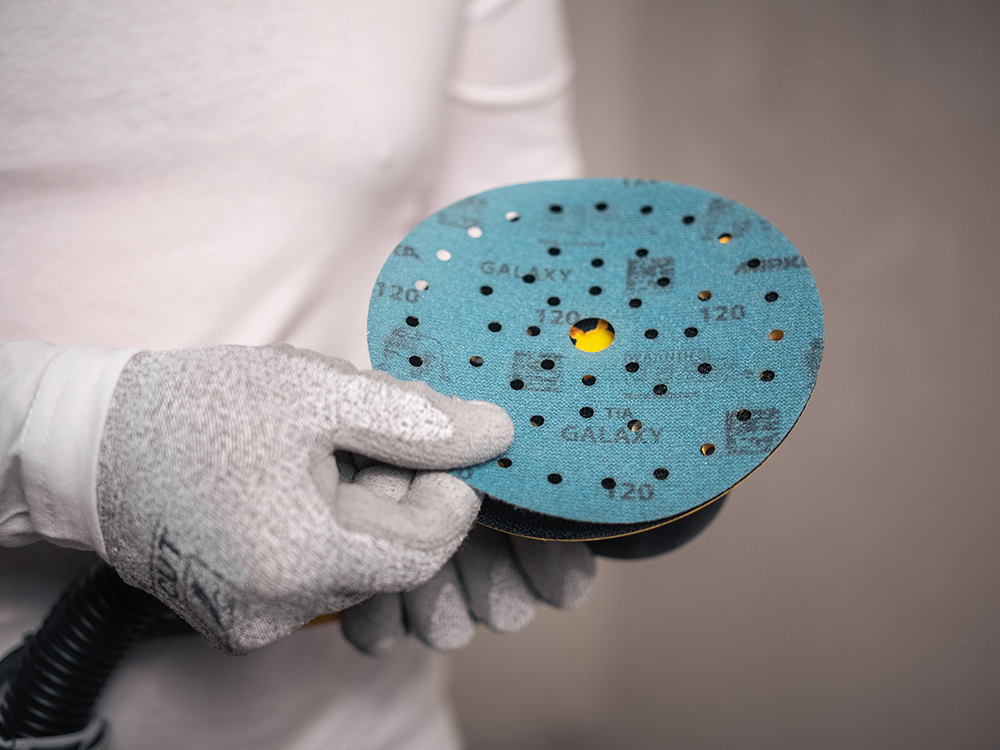

Mirka Galaxy is a new kind of high technology abrasive. It combines effectiveness with long use life, thanks to a new kind of self-sharpening ceramic grain, a clogging resistant coating and the new Multifit™ hole configuration.

Every aspect of the Mirka Galaxy serves together to turn it into a real multi-purpose abrasive. It is suitable for sanding both soft and hard materials as well as various substrates, thanks to its excellent clogging resistance and dust repellence.

Healthier workplace

Stop dust from getting into your lungs

Time saving

No cleaning after sanding, clean abrasives cut better

Money saving

Clogging resistance lets you sand longer with the same abrasive

High quality finish

Thanks to a finer scratch pattern

How to Achieve a High-Gloss Finish with Polishing

When it comes to interior design, a shiny high gloss finish on a painted wooden surface can be a real eye-catcher in interior spaces such as kitchens, but imperfections on the surface can be as eye-catching.

With Mirka’s solution for high gloss polishing of wooden surfaces, you can remove these imperfections, such as scratches and orange peel, and achieve a deep, glossy shine.

With the right combination of abrasives, polishes, and tools the job will be quick, easy and virtually dust-free, meaning you can save money as well as time spent on sanding and cleaning up.

Step 1: Sanding

To remove scratches and imperfections, sand the surface with a Mirka DEROS electric sander and Galaxy abrasive until the surface is completely matte. If there is heavy orange peel, sand the surface with Abranet Ace P1000.

Step 2: Damp Sanding

Switch to damp sanding with Abralon P3000 (make sure both abrasive and surface are wet). To protect the sander and dust extraction system from moisture, turn off the dust extractor or use Mirka Vacuum Block Disc.

Make sure the surface is completely sanded, then wipe it off with a microfibre cloth.

Step 3: Polishing

Polish the surface with Polarshine 10 and Lambswool Pad.

For an even deeper gloss, polish a second time using Polarshine 10 and a Yellow Waffle Polishing Pad (optional step).

Sanding Doors & Windows for Advanced Finishing: 3 Steps

Get a flawless finish with less dust and better productivity in your manufacturing by using Mirka’s dust-free solutions. Promising effortlessly efficient dustless sanding, the Mirka brand is known for its award-winning sanders.

Combine them with Mirka abrasives to achieve an end-result that exceeds expectations.

Door and window frames can be a challenge to sand, due the difficult shapes and working positions. With Mirka tools, sanding even trickier parts can be effortless and efficient.

1. Power Tools

When sanding door and window frames, our recommendation is the Mirka DEOS 353CV or the Mirka DEOS 383CV electric orbital sander, and for corner sanding the Mirka DEOS 663CV Delta electric orbital sander.

These tools are designed with the user’s health and comfort in mind, featuring a low profile, light weight, brushless motors and ergonomic design with minimal vibration levels.

Explore Sanders2. Abrasives

Mirka offers a wide range of effective abrasives and sandpapers for different applications. When sanding door and window frames, we recommend choosing the Mirka Abranet range of products.

The ground-breaking Abranet abrasive is fully formed out of mesh, meaning the entire surface area can be used for dust extraction. Abranet is available in different grits and strengths.

3. Dust extraction

Most Mirka power tools are offered with dust extraction capabilities. Simply by connecting the tool via a hose into a dust extractor, dust created from sanding is effectively fed into the dust extractor for a clean and safe work environment.

Not only is the dust removed from the working surface, the amount of dust in the workplace air is also significantly reduced. Mirka's M-class extractors are suitable for harmful wood dusts. However, we still recommend using a mask and other protective gear when sanding.

Expore Dust Extractors

Intermediate Sanding of Paint Coats on Wood

When painting wooden surfaces like cabinet doors or dining tables, you want to have a smooth finish when it is time to apply that final coat of paint, every layer of paint must be flawless.

No matter how careful you are, there is always a risk for bubbles in the surface, or particles such as dust sticking to the wet paint. The solution is to sand the surface between applying coats of primer and paint. With Mirka’s solutions, intermediate sanding can be fast, easy, and dust-free.

Sanding Between Paint Coats with Mirka Solutions

After each coat has dried, sand the entire surface with a Mirka DEOS or Mirka DEROS orbital electric sander. For best results, we recommend using Mirka abrasives such as Abranet, Galaxy or Iridium.

To avoid too aggressive material removal, with a risk of sanding through the paint layer, it is best to use medium grit abrasives (240-400).

Using a Dust Extractor when sanding helps minimize dust particles in the air. Your health and the paint layers will thank you later.

Mirka Galaxy

Mirka Galaxy is a new kind of high technology, self sharpening abrasive that is out of this world. Galaxy gives you the opportunity to refine your craft, making your processes less time consuming, saving you both time and money.

Explore Mirka GalaxyMirka Abranet

The multifunctional and classic Mirka Abranet is especially developed for sanding putty, primers, lacquers, composite materials and a wide range of other materials for industrial use. Abranet combines high performance and a long lifespan, making it a cost-effective solution.

Designed for dry sanding, by hand or with a machine, the true dust-free sanding characteristics result in a cleaner work environment, as well as a better surface finish.

Explore Mirka Abranet

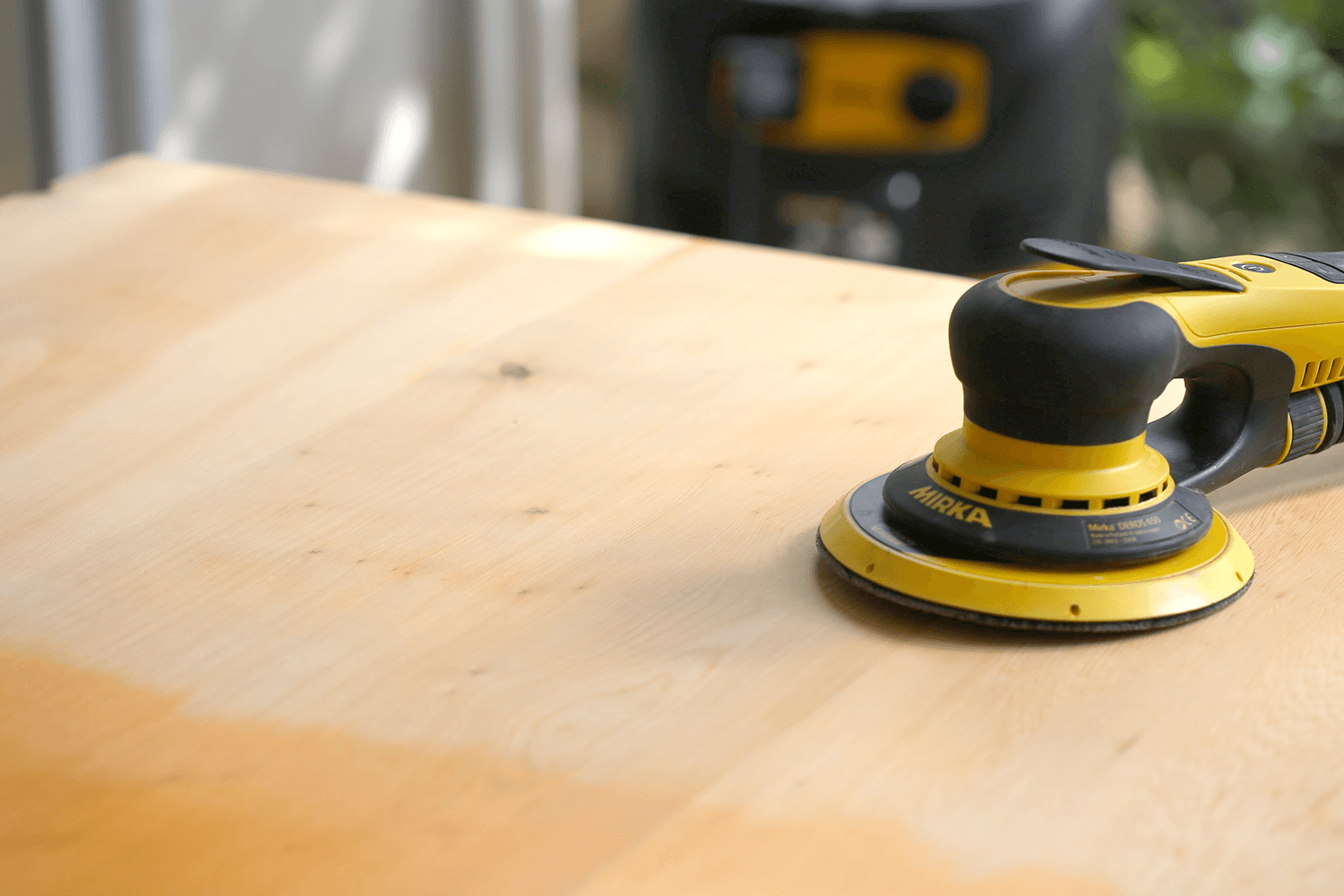

How to Sand Wood - Plane Wooden Surfaces and Boards

When using wood in construction and decoration projects, the sanding process is impossible to overlook, regardless of what type of wood you are using. A piece of wooden furniture, needs to look its best, and this is where a high quality sanding process is crucial.

A good sanding result is especially important for products where wood grain remains visible in the finished product, but also if you are planning on applying paint or lacquer. The better the preparation, the better the result.

Mirka offers abrasives and tools to help you achieve a flawless end result, together with our dust-free solutions which make it possible for you to sand with virtually no dust.

1. Tools

The first step to sanding wooden surfaces is choosing the right tool for the job. Mirka offers a wide range of electric sanders: the orbital Mirka DEOS sanders, and random orbital sanders in the Mirka DEROS product range.

No matter which one you prefer, both sander ranges are similarly well-engineered, featuring a low and lightweight ergonomic design to ensure you can sand for long periods without fatigue, with high manoeuvrability and precision.

Explore Sanders2. Abrasives

The choice of abrasive to use for the job depends on what type of wood you are sanding.

Mirka offers excellent all-round alternatives whether working with softer woods such as pine or a hard wood such as oak. Mirka's recommendations are Iridium or Galaxy, for when you want a premium paper abrasive that is both fast and efficient, or the Abranet family of abrasives, if you are looking for high material removal performance together with cost-effective sanding.

3. Dust Extraction

Dust is a natural side product of sanding, but it is a negative one. Not only does dust make your workspace look dirty, it can also have a hazardous effect on your health: the most dangerous dust is airborne, as by the time it settles on the working surface it has been in the air for long, for you to breathe. Long term exposure to dust from certain hard woods can be especially harmful.

Mirka's dust extractors can help you minimize the amount of airborne dust created from sanding. Combining the extractor with our tools and abrasives you will get a dust-free solution that is not only good for your health, it also reduces time spent on cleaning up after you have finished your work.

How to Sand Profiles & Contours Faster

Sanding profiles, corners, and curved surfaces may be tricky, but with Mirka’s abrasives you can:

Sanding complex parts can be done more efficiently and effortless by choosing Mirka abrasives. When sanding profiles, corners, and curved surfaces, for example, ceiling mouldings, door mouldings and floor mouldings, we recommend using either Goldflex Soft or Mirlon, depending on the type of surface and depth of contours you are going to sand. All concave, convex or the most complex shapes take shape with ease.

Step 1: Start Sanding

Start hand sanding with Goldflex Soft P150-P320 grit or Mirlon strips to remove imprefections on the surface. The worse the surface, the coarser the abrasive grit must be to start. If the surface is in better shape, we recommend you begin with a finer grit.

Explore GoldflexStep 2: Apply pressure

Apply pressure into the profiles:

Goldflex Soft

The soft and flexible Goldflex Soft has been developed for sanding profiled surfaces and irregular, difficult-to-reach details by hand. The foam base is grip friendly and applies pressure evenly, which reduces the risk of sanding through the surface. The special stearate coating prevents clogging.

Goldflex Soft offers a wider grit range compared to Mirlon. It can be used for intermediate sanding of painted surfaces when using finer grits than P240. More coarse grits than P180 can be used, if you want to remove paint, larger irregularities, and putty. Goldflex Soft has a flattening effect, which means that it removes surface unevenness better and more efficiently.

Explore GoldflexMirlon

Mirlon is a flexible, three-dimensional fibre sanding material that is easy to use on profiled surfaces and contoured shapes, producing an excellent finish, thanks to its special non-woven structure. Mirka Mirlon is ideal for matting of surfaces and creates an excellent base for the next lacquer layer.

Explore Mirlon

Step by Step to High-End Result

Oiling woodwork is for protecting the wood and for enhancing the natural grain of the surface. It gives the wooden surfaces a natural sheen and texture and makes the grains stand out. Wood oiling is widely used for a variety of high-end finish applications, such as maintenance of countertops, oiling furniture, refinishing kitchen countertops and recoating old surfaces.

Before, in-between and after the oiling, you need to ensure that the wood has been properly sanded. Mirka offers a wide range of sanding solutions to prepare the wood before oiling.

Note: Always follow the oil or wax manufacturer’s recommendations.

Recommended products

For the perfect high-end finish, we recommend using the following Mirka products:

Step 1: Prepare the surface

Sand the wooden surface with either

Mirka Abranet or Mirka Galaxy abrasives up to P150 with a Mirka DEROS or Mirka LEROS-S electric sander (for large surface areas.)

MIRKA ABRANET features a net structure resulting in extremely efficient on-tool dust removal that improves both the work quality and the working environment. Most oiled surfaces are hardwood, and exposure to hardwood dust is hazardous for your health.

Note: We recommend using Abranet on untreated wood surfaces. There is a risk of clogging if it is used on already oiled wood.

MIRKA GALAXY combines effectiveness with long life, thanks to a new self-sharpening ceramic grain and a clogging resistant coating. The edge wear resistance of Galaxy is perfect for challenging wooden surfaces in terms of cutouts and sharp corners. We recommend using Galaxy if the wooden surface is already oiled and the purpose is maintaining the surface.

Overall, it is important not to sand with too fine grits, because this closes fibers in the wood which results in the oil or wax not penetrating into the surface. We recommend using P120-150 grit for surfaces such as flooring and P150-180 grit for finer surfaces such as furniture, depending on guidance from the oil manufacturer.

Step 2: Apply oil (no brush)

Step 3: Intermediate sanding or recoating old surfaces

When the coating has absorbed, sand with one of the following:

Step 4: Finishing (optional)

After the final layer has dried:

There is something special about a piece of furniture that offers something more than functionality. Furniture making can be seen as a form of expression and has seen many designs...

The vehicle refinishing process can be time-consuming and painstaking, requiring great attention to detail. The results have to be meticulous - free of holograms and defects. Any option that saves...

When it comes to achieving a flawless, mirror-like finish on various surfaces, Mirka Polarshine polishing compounds have become the go-to choice for professionals and enthusiasts alike. With innovative waterbased and...