A guide to sanding and finishing an epoxy table

There is something special about a piece of furniture that offers something more than functionality. Furniture making can be seen as a form of expression and has seen many designs...

Facing harsh conditions with salt, water and wind, marine surfaces need to be built to last, as well as regularly maintained and expertly refurbished to keep that first-class look. When it comes to marine surface finishing, from boat manufacturing – including high-end yacht production – to boat refurbishing and restoration, Best Abrasives can deliver.

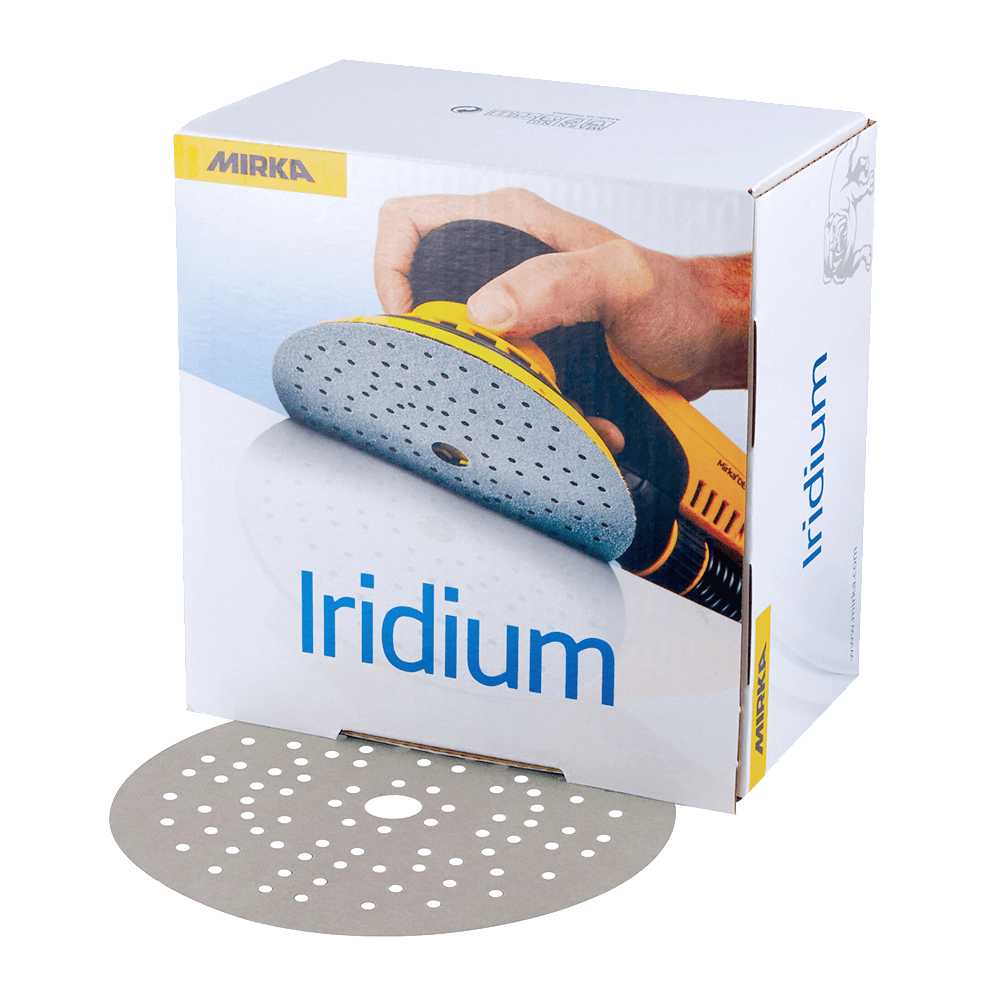

Choosing dust-free and ergonomic Mirka products isn’t only a health-conscious choice, but it will also improve your profitability, productivity and efficiency. Mirka’s sanding, compounding and polishing products together with our award-winning tools suit everything from heavy-duty sanding of composite moulds to smoothening out the final gel coat finish – from small scale to high volume production. If you are looking for high-rate efficiency and a world class finish for your marine surfaces; read on to learn more about innovative solutions that give you better results with fewer steps.

Mould Gelcoat Sanding Process

Step 1

Step 2

Step 3

Step 4

Step 5

Proper surface preparation on both the plug and mould is crucial for successful yacht or boat construction. Any flaws on the surface of the plug will be transferred to the mould, and then to subsequent parts made from the mould. A smoother outer surface on the mould will necessitate less finishing work, saving both time and money. Watch the video to see the process.

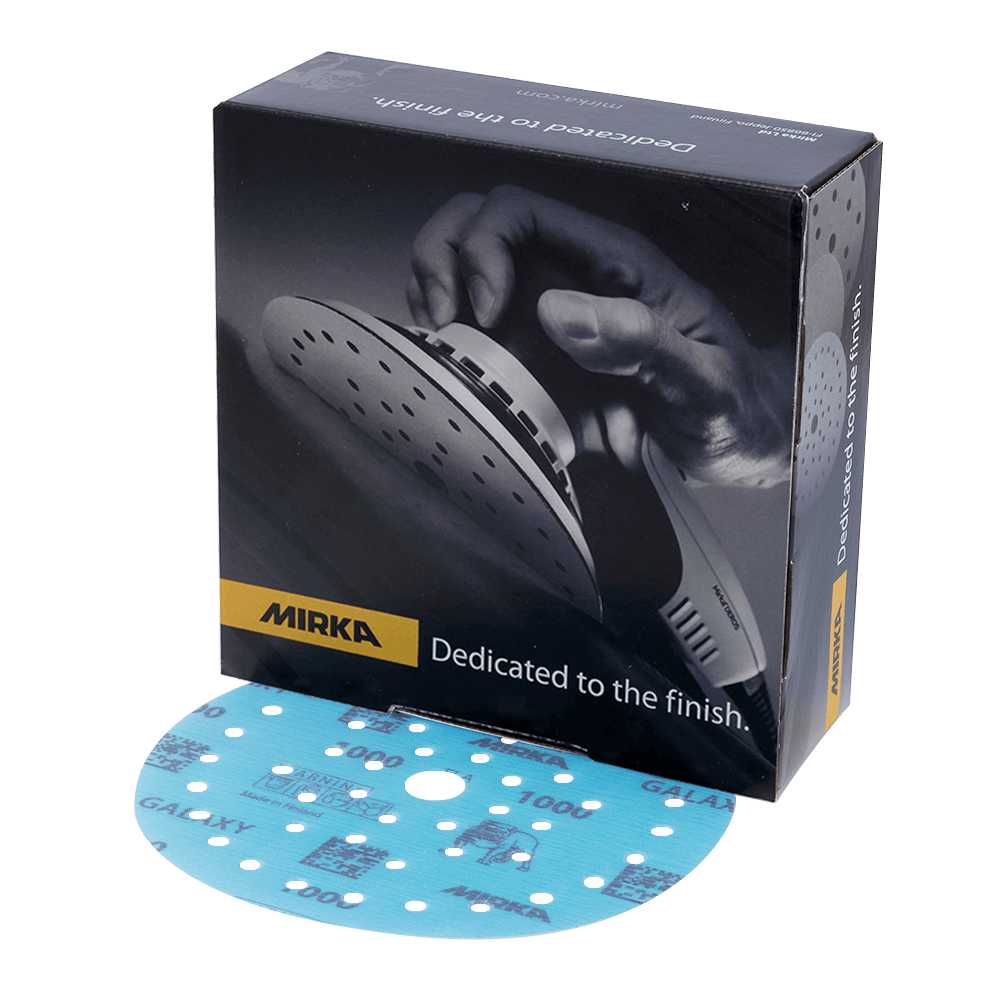

For orange peel surfaces, start sanding with Mirka Galaxy 600 grit together with Mirka Deros Sander.

The starting point of this surface is good, we therefore start from Galaxy grit 800 using a Net Interface.

Clean the surface between every sanding step to avoid contamination and get a better visibility of the sanding progress.

Continue sanding until scratches are reduced. Use Galaxy 1200 or 1500 grit together with a Net Interface.

Use Galaxy 2000 grit together with a Net Interface.

When wet sanding, turn off the dust extractor. Use Mirka Abralon 3000.

Next, follow the Polishing process below.

Mould Gelcoat Polishing Process

Step 1

Step 2

Step 3

Proper surface preparation on both the plug and mould is crucial for successful yacht or boat construction. Any flaws on the surface of the plug will be transferred to the mould, and then to subsequent parts made from the mould. A smoother outer surface on the mould will necessitate less finishing work, saving both time and money. Watch the video to see the process.

Use Polarshine 45 and a Lambswool Pad Pro together with Mirka ARP-B Polisher.

Polish the surface to eliminate sanding scratches.

Wipe off any excess polishing compound between the polishing steps.

For dark colours:

Change to a Black waffle foam pad, apply Polarshine 12 Black polishing compound and polish the surface.

For light colours:

Attach a Waffle polishing foam pad and apply Polarshine 12 to the pad and polish the surface.

Finally, wipe off excess polishing compound.

Conditioning of Gelcoat

Deep Cleaning

Compounding / Cleaning

Swirl Removal / Polishing

Surface Protection

It is easy to condition a gel coat finish with Mirka solutions. Use Abralon for machine sanding the surface, work with Polarshine to compound, to remove swirls and to polish, and finish the job by protecting the surface.

You can find the perfect match for your polishing needs with this handy compound grade scale. We also offer complete finishing kits to make it even easier.

Use Polarshine 35 or Polarshine 45 + Lambswool Pro Pad.

Use Polarshine 10 + Yellow Waffle Pad.

Glass & Scratch Polish

Preparation

Step 1 - Sanding

Step 2 - Sanding

Step 3 - Polishing

Glass windows can accumulate scratches and small defects. Instead of replacing, refurbish: blemishes can easily be removed with sanding and polishing using Mirka products. Depending on the depth of the scratches and quality of the material, Mirka offers various solutions designed to give you the perfect finish.

Spray the surface and wipe it clean.

Starting with Abralon 360 grit and DEROS Sander, sand the surface to suit the depth of the scratches. Wipe the surface with a sponge.

Move to finer Abralon 500 grit. Wipe the surface again.

Continue sanding with Abralon 600 grit.

Sand with Abralon 1000 grit, then move on to the polishing process.

Polish with ARP-B Cordless Polisher, Polarshine E3 and Lambswool Polishing Pad Pro.

Below waterline

Mirka Deros 150mm Sander

Leros & Leros-s Sander

Mirka Galaxy Abrasive Discs

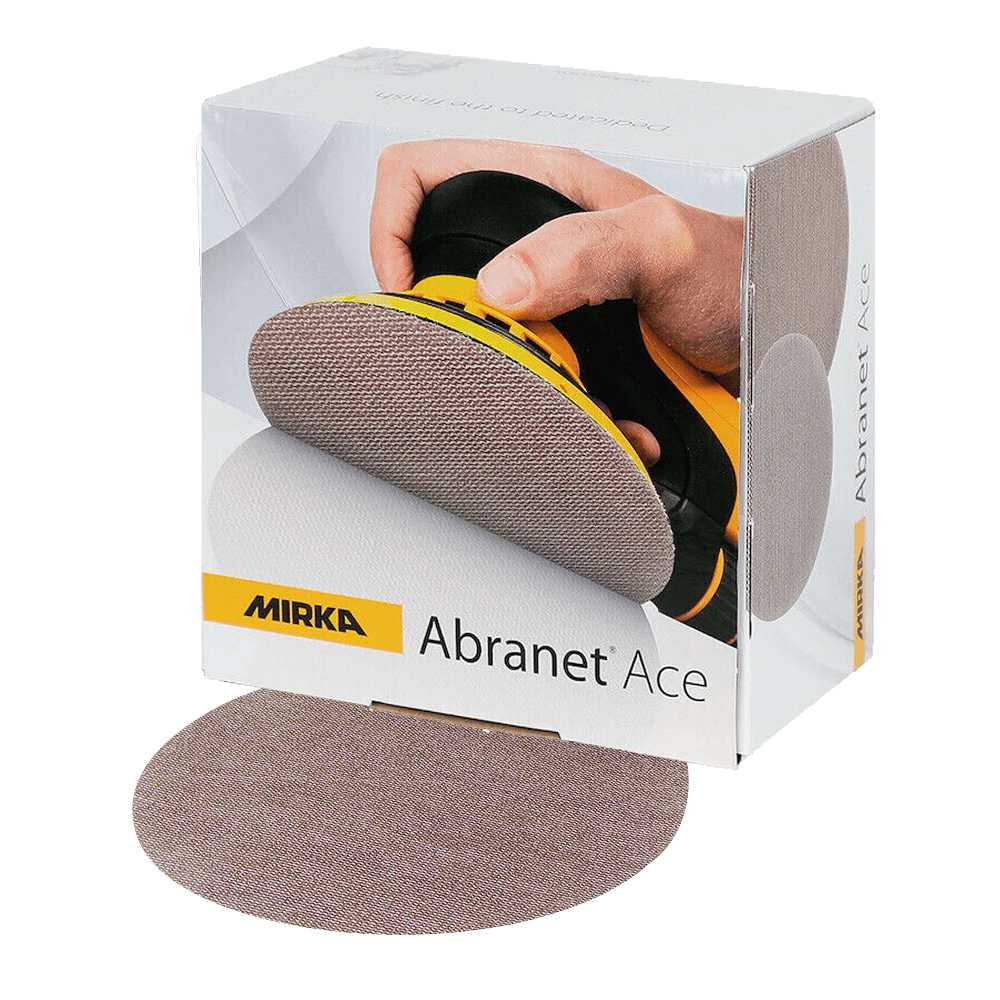

Abranet Ace HD

Dust Extraction

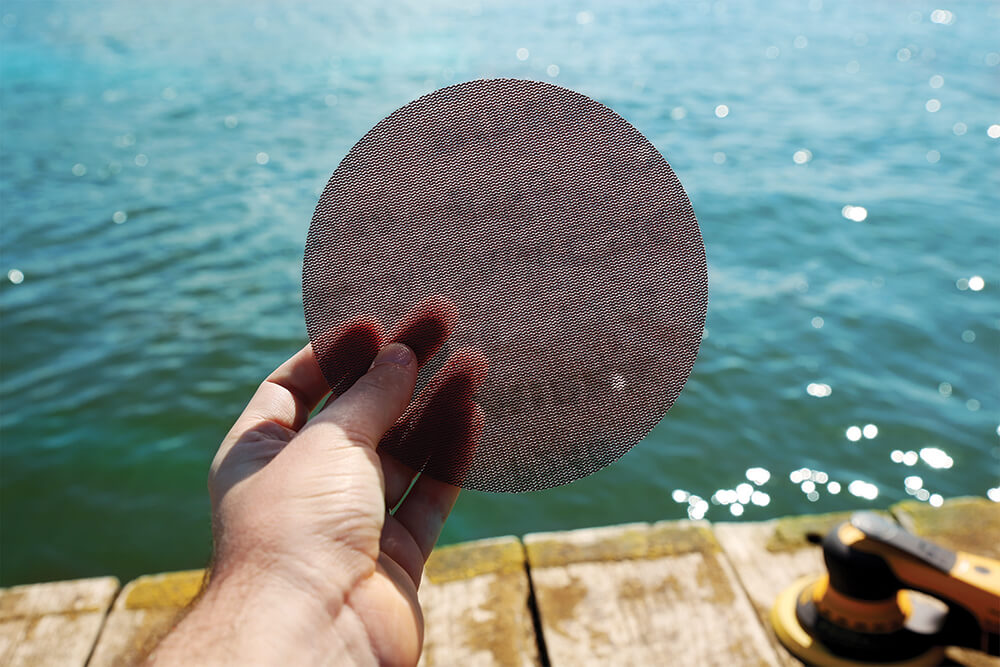

When sanding below the waterline, we recommend our dust-free sanding solutions – whether you’re working on new or old fibreglass surfaces. The Abranet Ace HD resists high wear and tear and is ideal for heavy-duty applications: combine it with an electric rotating machine fitted with a dust suction hood. Mirka’s Multifit, self generating grain abrasive - Galaxy delivers remarkable results, especially on hard surfaces. Its precision coating won’t get clogged as it practically repels dust and its grains stay sharp.

The Mirka Deros is the lightest 150mm sander in the world. Fitted with integrated vibration sensor and Bluetooth low-energy technology, it connects with the myMirka app - which allows you to track your vibration exposure, RPM and more. It has plenty of power to get the job done quickly; with a performance comparable to a conventional 500W electric sander, it maintains constant speed even under heavy load.

Specially designed for comfort, the Leros-s allows you to sand large areas, even when in tight areas. The sander is brushless - meaning extended efficiency and reliability. The sander's 3.2 kg light weight makes it more comfortable to operate for longer periods of time, and the sanding head's extensive flexibility enables a more ergonomic working position and easier access to surfaces from different angles.

The ceramic grains of the Galaxy are engineered not to dull, as once the edge of the abrasive grain breaks off it simply forms new edges, making it possible for the Galaxy to continue cutting – from edge to edge. The self-sharpening ceramic grains allow for a winning combination of long life, fast cut and easy polishability.

Abranet Ace HD is durable and tough with ceramic grains. The strong net structure resists high wear and tear and the product is ideal for heavy-duty applications. The improved woven mesh backing increases the lifetime of the abrasive, and makes the sanding process faster. The strong bonding of ceramic grains provides fast stock removal for heavy duty sanding tasks, such as sanding of various wood types, various composites, and stripping of old paint and lacquer.

The Mirka 1230M AFC Dust Extractor is a highly efficient vacuum, combining high performance power and whisper-quiet operation to deliver a dust extraction solution second to none. Designed for professional use, the 1230Ms powerful 1200 watt motor extracts 4500 litres of air every minute, yet fits inside a compact unit that can be stowed away under a counter or behind a bench.

Top & Clear Coat Sanding process

Step 1

Step 2

Step 3

Step 4 - Polishing

It takes time, effort, and knowledge to build and maintain the perfect yacht or boat. At the manufacturing stage, Mirka's marine solutions can make the surface finishing processes more efficient and with a better end result.

The quality of the surface finish and coating can be taken to the next level by sanding or polishing, or removing smaller imperfections such as orange peel, to get an even better lustre.

Topcoat marine paints can be applied after surface preparation to ensure that the topcoat paint adheres to the substrate and provides a long-lasting finish that can resist a variety of weather conditions.

Start sanding with Mirka DEROS 650CV using a Net Interface and Galaxy 1200 or 1500 grit.

Clean the surface between every sanding step to avoid contamination and get a better visibility of the sanding progress.

Continue sanding with Galaxy 2000 grit.

For light colours:

Polish the surface with Polarshine 35 and a Lambswool Pad PRO together with Mirka ARP-B Polisher to eliminate sanding scratches.

For dark colours:

For dark coloured surfaces, continue with Polarshine 12 Black with a Black Waffle

foam pad to remove any polishing marks, haze and holograms.

Wipe off any excess polishing compound.

Same day dispatch

All orders received by 2pm are dispatched on the same day, with express post options Australia-wide.

Best Price Guaranteed

Find a better price online or in store and we'll beat it by 5%*

Outstanding Service

Contact our helpful team at info@bestabrasives.com.au

or by phone on 02 8036 8478.

There is something special about a piece of furniture that offers something more than functionality. Furniture making can be seen as a form of expression and has seen many designs...

The vehicle refinishing process can be time-consuming and painstaking, requiring great attention to detail. The results have to be meticulous - free of holograms and defects. Any option that saves...

When it comes to achieving a flawless, mirror-like finish on various surfaces, Mirka Polarshine polishing compounds have become the go-to choice for professionals and enthusiasts alike. With innovative waterbased and...